The Importance of Scissor Lift Training and Re-Training

Working at heights is integral to the success of many construction and maintenance projects. Without the right training and equipment for aerial access operations, mishaps could be inevitable.

In recent years, falls from significant heights above ground have resulted in several unpleasant incidents. Aside from the devastation to workers involved, it also demoralizes other members of staff. There is also the aspect of losing money due to workers health cost and short-notice hiring. There are several types of aerial access equipment used in work operations above ground.

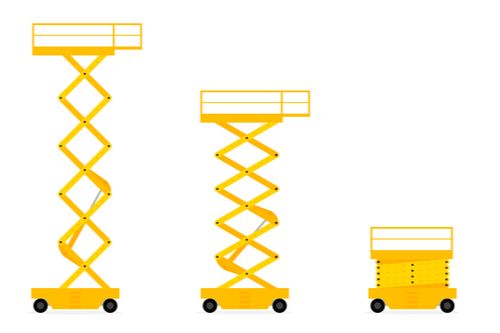

Scissor lifts constitute a majority when it comes to equipment preferred for accessing massive heights without hassle.

That is why this piece focuses on the importance of training staff on using scissor lifts. With the in-depth analysis in this short piece, you will have relevant information to keep your staff safe at heights.

Scissor Lift Training

An aerial work platform with upward, vertical displacement (scissor lifts) allows work at challenging heights.

An aerial work platform with upward, vertical displacement (scissor lifts) allows work at challenging heights.

- Training workers on scissor lift training includes,

- Equipment use

- Reevaluation requirements

- Transit operations

- Scissor lift weight limit

- Hazard identification

- Defect reporting and preventative maintenance

Scissor lifts are a highly valuable tool in many Ontario workplaces. However, scissor lifts also come with their fair share of hazards and inherent risks to workplace safety.

That’s why scissor lift training is necessary.

The Importance of Scissor Lift Training

Provides essential knowledge on wind monitoring during lift operation

Having correct readings on wind movements is essential to safe and efficient scissor lift operation.

Having correct readings on wind movements is essential to safe and efficient scissor lift operation.

Scissor lift training provides your employees with relevant facts on wind speeds and direction.

With access to these facts, it will be less likely for your scissor lift to tip over during operation.

Scissor lift training saves cost, prevents accidents, and sustains productivity.

Terrain assessment information

Having essential facts on operating terrain such as slopes and areas subtended at an angle prevents accidents.

With scissor lift training, your employees and machinery will remain safe from accidents and damage.

Environmental considerations

Considering above-ground fittings like electrical lines and other installations capable of interfering with your scissor lift is crucial.

Collapse prevention and outrigger fitting

Preventing guardrails, outriggers, and other scissor lift parts from falling off is vital.

Also, vital accident prevention from weight limit and safety system monitoring promotes safe scissor lift operation.

Scissor Lift Retraining

After every thirty-six (36) months, it is mandatory for scissor lift operators to undergo refresher scissor lift training.

After every thirty-six (36) months, it is mandatory for scissor lift operators to undergo refresher scissor lift training.

Retraining your staff on scissor lifts operation enhances their understanding of the aerial access equipment.

Most times, relevant information not included in previous scissor lift training get included in refresher courses.

Enrolling your staff for such training keeps them informed on the latest scissor lift safety trends.

When your employees get relevant information on scissor lifts, accidents get prevented and productivity does not slump.

How Can Advanced Consulting and Training (ACT) Help

If the information above drives you to enlist your staff in scissor lift training, ACT is the right company to call upon for maximum workplace safety compliance and prevention.

Contact us today, and let our experienced team will deliver essential trainingon how to manage scissor lifts.