Material Handling Safety Tips in 2024

Are you prioritizing the well-being of your team in material handling operations? Ensuring a safe work environment goes beyond routine tasks – it’s about implementing robust material handling safety tips that protect your workforce from avoidable hazards. In today’s fast-paced industries, the emphasis on this aspect of the workplace is more critical than ever.

In this blog from Advanced CT, discover some material handling safety tips that foster a culture of protection, collaboration, and continual improvement in material handling practices.

Proper Training Is Key

When it comes to material handling safety, a well-trained team is your first line of defence. It’s crucial to ensure that everyone involved in material handling undergoes comprehensive safety training programs. These programs should go beyond just an initial session—regular refreshers on safe lifting techniques, proper equipment usage, and hazard awareness are fundamental. By consistently reinforcing these practices, you’re empowering your workforce to handle materials safely and confidently.

Regular Equipment Maintenance

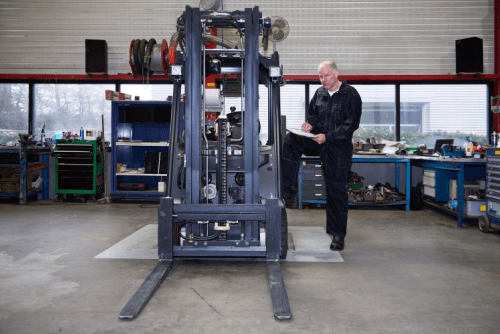

Just as vital as using the right equipment is maintaining it properly. Scheduling routine maintenance for all material handling equipment is crucial to prevent unexpected breakdowns. Equipment failure can compromise safety, so by staying proactive with maintenance, you reduce the risk of accidents and ensure a reliable, safe working environment for your team.

Utilize Equipment Wisely

Handling heavy or bulky materials requires the right tools for the job. Always use appropriate equipment such as forklifts, pallet jacks, or hoists for various tasks. Regularly inspect these tools to ensure they’re in optimal working condition. A well-maintained and functional equipment fleet significantly reduces the risk of accidents and ensures smoother operations.

Ergonomics Matter

Encouraging proper lifting techniques is crucial in minimizing the risk of injuries. Emphasize the use of leg muscles, maintaining a straight back, and avoiding sudden movements. Additionally, investing in ergonomic tools like adjustable workstations or lift-assist devices can significantly reduce strain on your employees’ bodies, contributing to a safer working environment.

Clear Communication

Establishing clear communication protocols among team members during material handling operations is essential. Whether it’s through signals, verbal cues, or visual signs, effective communication ensures that everyone is on the same page, reducing the chances of accidents and ensuring coordinated movements. Encourage an open dialogue among your team to promote a safer working environment.

Organize Workspaces

A tidy workspace is a safe workspace. Maintaining clean and organized work areas significantly reduces tripping hazards and the risk of accidents. Properly storing materials prevents them from falling or obstructing pathways, minimizing potential dangers and creating a safer environment for everyone involved.

Personal Protective Equipment (PPE)

The safety of your team is paramount, and personal protective equipment (PPE) plays a critical role. It’s imperative to require the use of appropriate gear such as gloves, helmets, and steel-toed boots during material handling tasks. Ensuring the availability of these items and enforcing their usage is essential to protect your workforce against potential injuries. By prioritizing PPE, you’re actively safeguarding your team from avoidable hazards.

Assess and Mitigate Risks

Conducting regular risk assessments is a proactive approach to identifying potential hazards. By identifying these risks, you’re better equipped to implement effective measures to mitigate them promptly. This not only prevents accidents but also demonstrates a commitment to proactive safety measures, fostering a culture of prevention within your workplace.

Team Collaboration and Support

Creating a culture of safety within your organization is more than just protocols—it’s about empowering your team. Encourage an environment where employees feel confident reporting unsafe conditions or behaviors without fear of repercussions. Prioritize safety over speed and foster a collaborative atmosphere where safety concerns are addressed promptly and constructively.

Continuous Improvement

Safety protocols should always evolve based on feedback, incidents, or industry best practices. Regularly reviewing and updating safety protocols is crucial to ensure they remain effective and relevant. Embracing a culture of continuous improvement demonstrates a commitment to the ongoing safety and well-being of your workforce.

Ensuring material handling safety isn’t just a regulatory requirement; it’s a commitment to the well-being of your workforce. By integrating these tips into your safety training program and daily operations, you pave the way for a safer workplace environment in 2024 and beyond.

Advanced CT- Leaders in Workplace Health & Safety Solutions

Ready to elevate your material handling safety standards? Please contact us at Advanced Consulting and Training Ltd. With a legacy of delivering prompt, certified health and safety solutions since 1998, our team of professionals ensures comprehensive workplace safety, from working at heights training to site audits and consulting. Partner with us for CPO-approved programs, flexible scheduling, and a commitment to unmatched support and discounts. Elevate your safety practices with Advanced CT today!