Remain Diligent with Lock Out Tag Out Procedures

OHS defines lock-out/tag-out (LOTO) protocols as procedures designed to protect employees from unexpected machinery operations. It also defines LOTO protocols as practices designed to keep workers safe from the release of hazardous energies during operation.

Employers must ensure due diligence from their staff when operating or maintaining potentially dangerous equipment. Ensuring the right practices are adopted makes sure accidents from non-routine activities never take place.

Why is Lock Out/Tag Out Essential?

Machines scheduled to undergo maintenance usually contain a form of potentially dangerous energy capable of causing significant harm. These dangerous forms of energy could be mechanical, chemical, electrical, thermal, or other sources.

Carrying out maintenance on equipment without proper lockout/tag-out exposes workers to unexpected dangers that could prove fatal. A sudden ignition could lead to the release of energy during maintenance. Following proper lock and tag-out procedures is vital for safety.

What Should Lock Out and Tag Out Procedures Contain?

Businesses should have a program detailing instructions and other important information to complete lock-out procedures. Such a document should contain:

- Hazardous energies covered by each procedure

- De-energizing or energy-isolating devices available

- Maintenance or operating procedures

- Required tools

- Staff to carry out the lockout/tag-out and time to complete the maintenance

Apart from these, the program should also contain:

- Information on the location and installation steps of lockout devices

- Steps to verify energy isolation

- Information on how energy stored in machinery is isolated

- The mane of machine, process, or equipment used in isolation and shutdown process

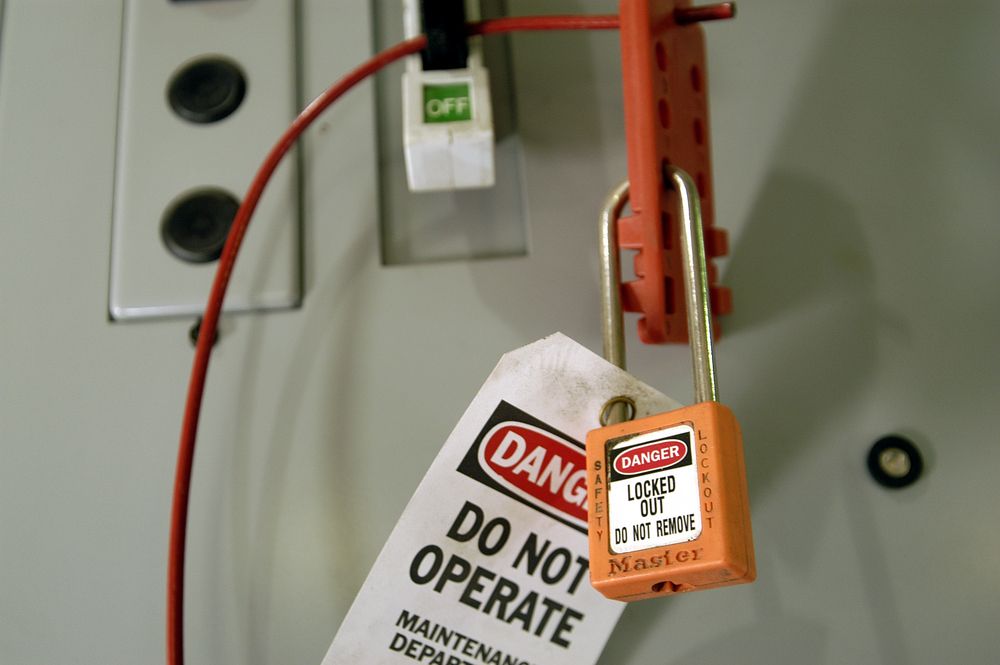

Programs that describe lock-out and tag-out processes may also contain images of described items for clarity.

Steps for a Safe Lock Out/Tag Out Procedure

Steps for a Safe Lock Out/Tag Out Procedure

Comprehensive lock-out and tag-out procedures typically involve five steps. Here’s a detailed look at each one and how to carry out maintenance activities safely:

Step 1: Preparation for Shutdown

An authorized worker will identify the machine, equipment, or process that requires lockout. They will also identify which sources of energy are present and what lockout device will be used.

Step 2: Notification

The authorized worker will notify all affected personnel. They should inform them of the following:

- What is being locked/tagged out

- Why it is being locked/tagged out

- Approximate length of time the system will be unavailable

- Who is responsible for the lock-out/tag-out (if it’s not them)

- Point of contact for more information

Step 3: De-energizing Machinery

Follow the shutdown procedures (from the manufacturer or employer). Ensure that all controls are in the “off” position and make sure that all moving parts have come to a complete stop.

Step 4: Lockout & Tag out

When the system’s energy sources are locked, there are guidelines to follow to ensure that the lock cannot be removed. Guidelines include:

- Each lock should only have one key

- All keys must be removed from locks and kept with the person who locked it

- There should be as many locks on the system as there are people working on it. (i.e., if three workers are required to operate it, there should be three locks present)

Step 5: Verification of isolation

Before any work begins, it’s crucial for you to verify that the system has been locked out properly. There are several ways you can do this:

- Try to activate the machine and observe the results (push buttons, switches…etc.). No response means isolation was successful (don’t forget to put controls back to the “off” position)

- Visual inspection (electrical connections, suspended parts…etc.)

- Equipment testing (test circuitry, check the pressure and temperature gauges)

Adopting the five steps above makes it easy to carry out and complete effective lock-out and tag-out procedures with ease. CCOHS outlines a 9-step procedure for employers to use for a lockout/tag-out protocol.

Advanced Consulting & Training – Lock-Out/Tag-Out Safety Program

During machinery maintenance, workers are exposed to several hazards that may prove fatal. However, companies that recognize lock-out/tag-out procedures in their operations offer better protection for their employees’ safety.

Machinery is to be fitted with the necessary safeguards if they pose a risk to workers’ physical health. Hazardous energies must be controlled to prevent chemical and electric accidents or other injuries.

At Advanced Consulting & Training, we offer a safety program for Lock-out/Tag-out procedures. Our workshop is designed for participants who have little to no working knowledge of how to perform a LOTO procedure. We also have workshops designed as a refresher course for more experienced workers.

If you’re ready to start building a safer workplace for you and your employees, contact Advanced Consulting & Training to learn more about registering for a safety program!